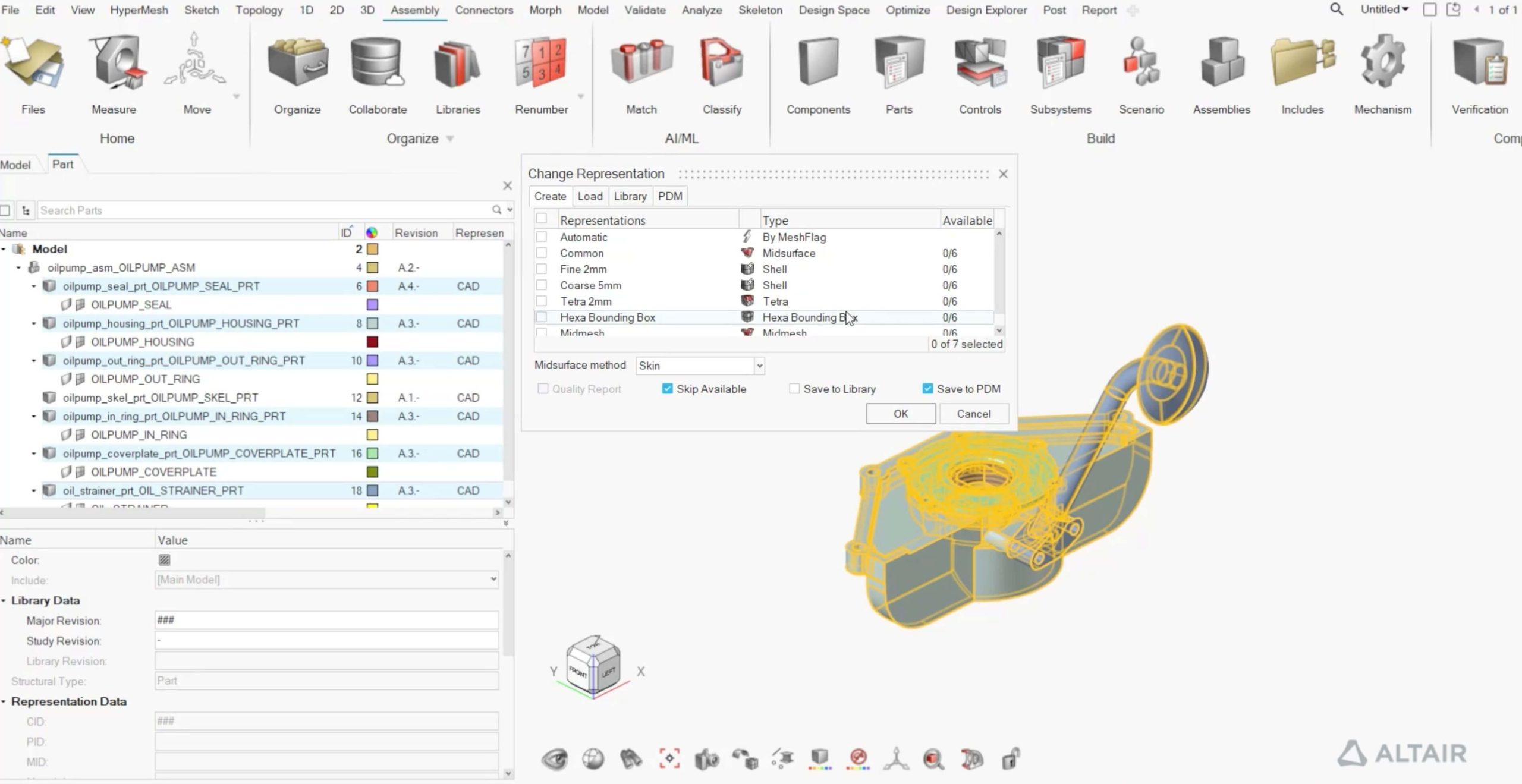

Its core features span the entire FEM workflow—from initial modeling to results visualization—with advanced tools for meshing, complex model management, and seamless enterprise integration.

Thanks to an intuitive interface, intelligent workflows, AI integration, and PDM system compatibility, HyperMesh enables engineers to reduce time-to-simulation, improve model quality, and accelerate technical innovation.

Direct FEM and geometric modeling

HyperMesh enables fast creation, editing, and evaluation of design alternatives through direct modeling of both geometry and FEM models. Edits can be applied directly to the mesh, streamlining iterations in early development stages and reducing setup time.

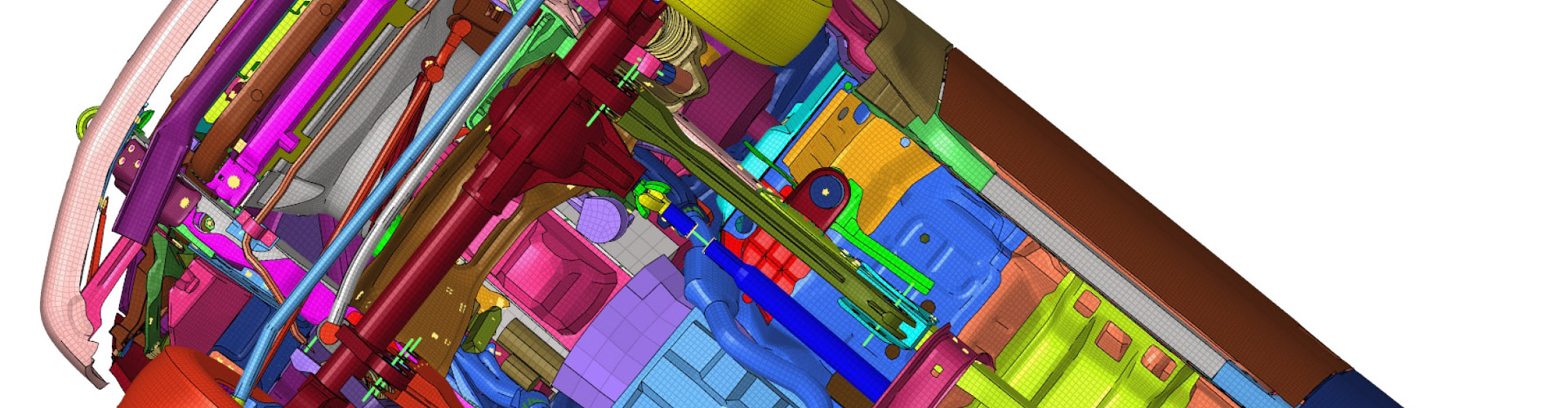

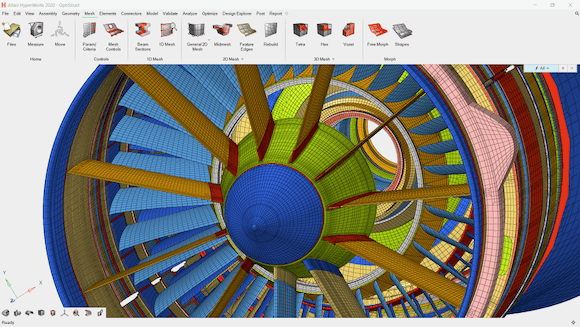

Advanced management of complex models

Structured handling of large assemblies is made possible through the use of Parts, Subsystems, and Connectors. This modular modeling approach simplifies model assembly, variant management, and load case definition across multi-product environments.

Integration with PDM systems and revision traceability

HyperMesh integrates seamlessly with leading PDM systems, supporting shared libraries and revision control. This ensures data consistency and traceability among team members, enabling efficient collaboration in distributed design environments.

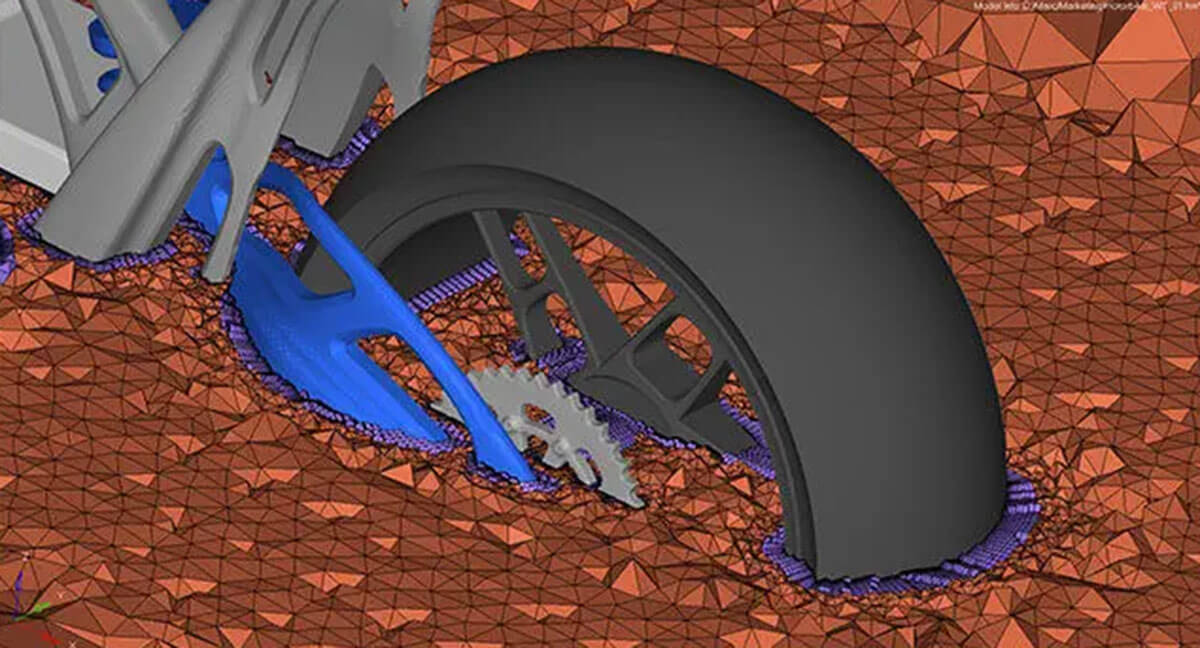

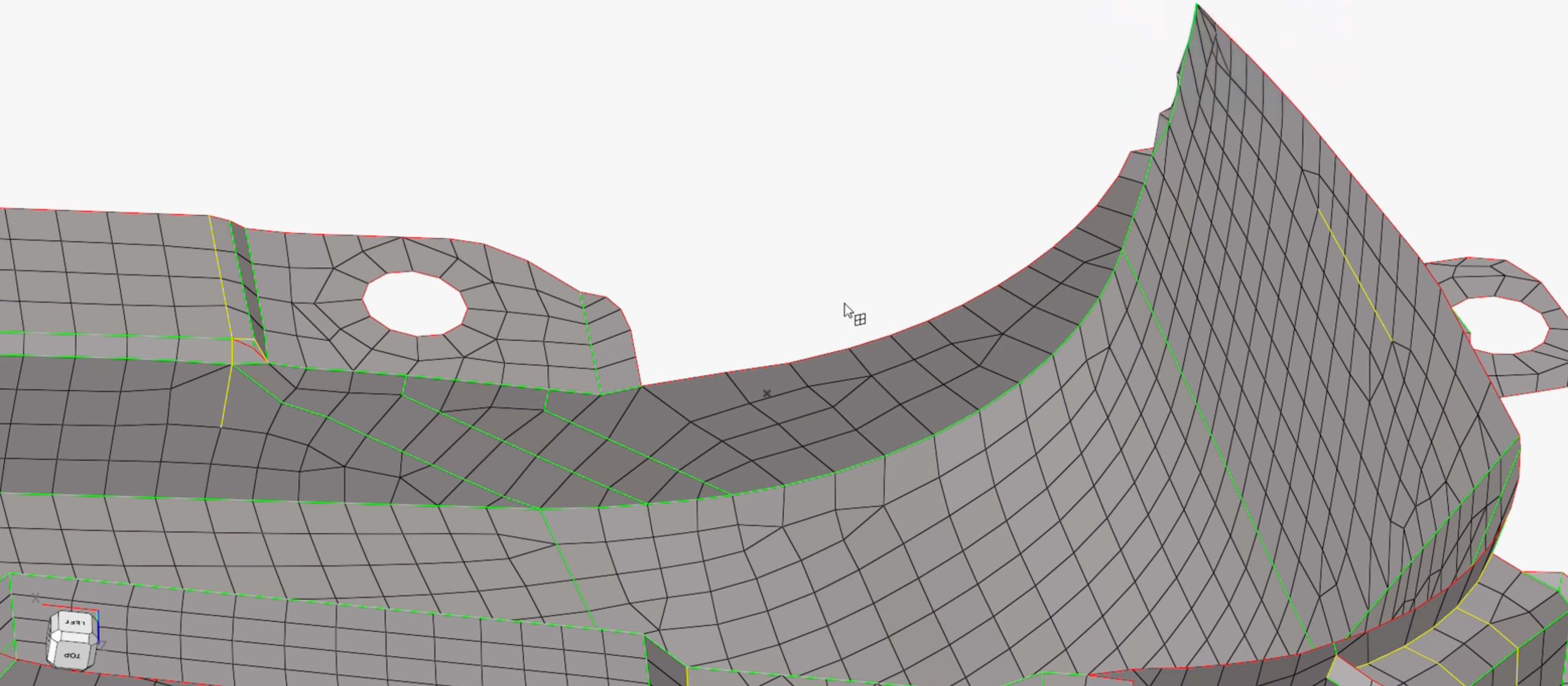

High-quality meshing and advanced control

The meshing toolkit offers full control over both surface and solid mesh generation, including advanced features such as mid-surface extraction, midmeshing, hex meshing, and automatic refinement. The result is high-fidelity meshes ready for analysis, with automated cleanup and topology optimization options.

Interactive morphing for rapid iterations

With HyperMesh’s interactive mesh morphing tools, engineers can quickly reshape FEM models without relying on external CAD software. This accelerates conceptual development and simplifies model adaptation to new design conditions or structural constraints.

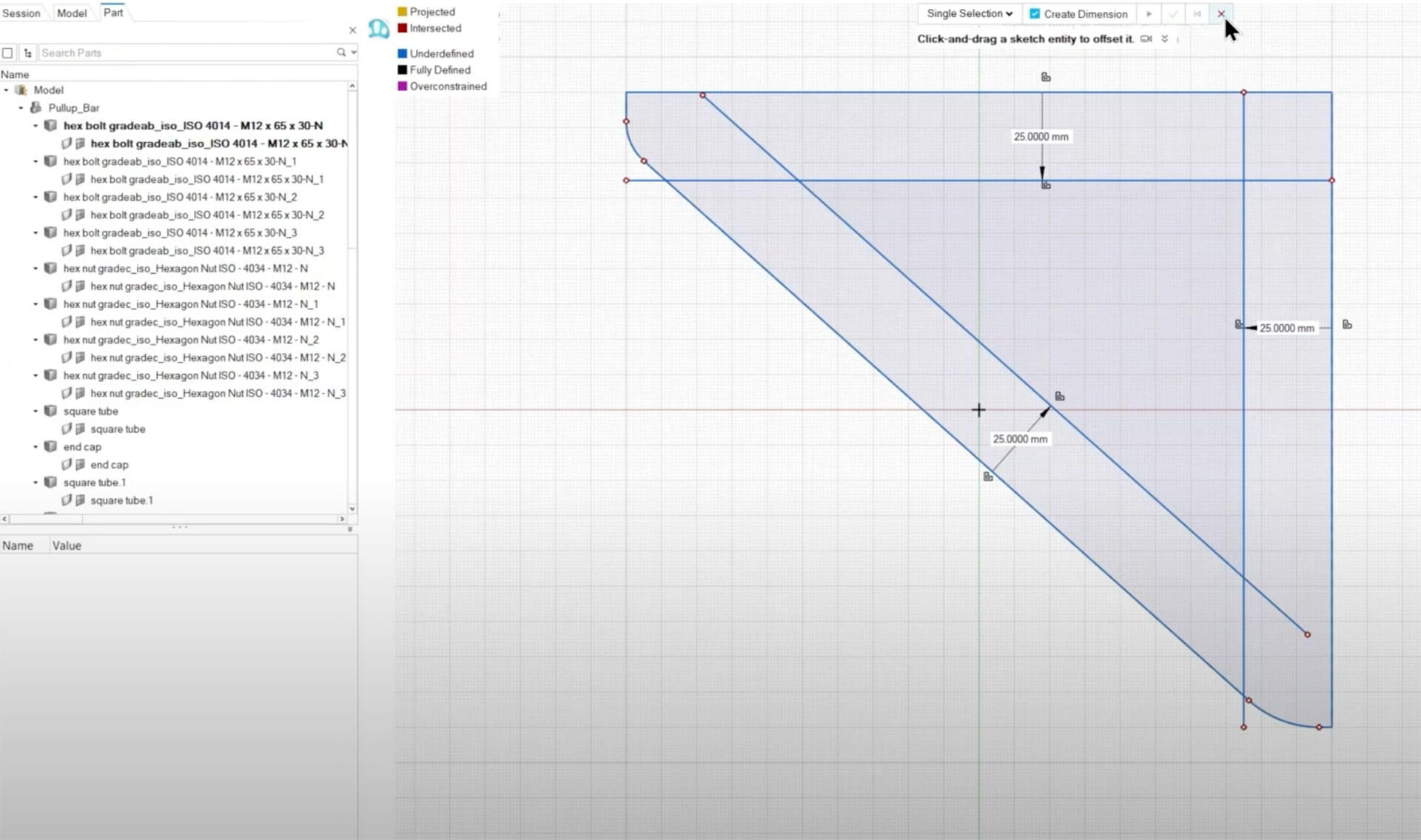

Efficient sketching and reverse engineering

HyperMesh includes precision sketching tools for generating or editing 2D/3D geometry. Reverse engineering capabilities allow users to reconstruct geometry from existing meshes, supporting the evolution of designs toward structural and functional optimization.

Optimized design space configuration

Setting up the Design Space for topology optimization is straightforward and guided. Dedicated tools enable even users with limited CAD experience to prepare models for simulations targeting mass reduction, stiffness, or structural strength.

Skeleton modeling for structural optimization

HyperMesh supports skeleton modeling to create simplified yet engineering-relevant models ideal for early-stage analysis and conceptual optimization. Users can define structural elements such as beams, panels, and joints, with real-time section editing.

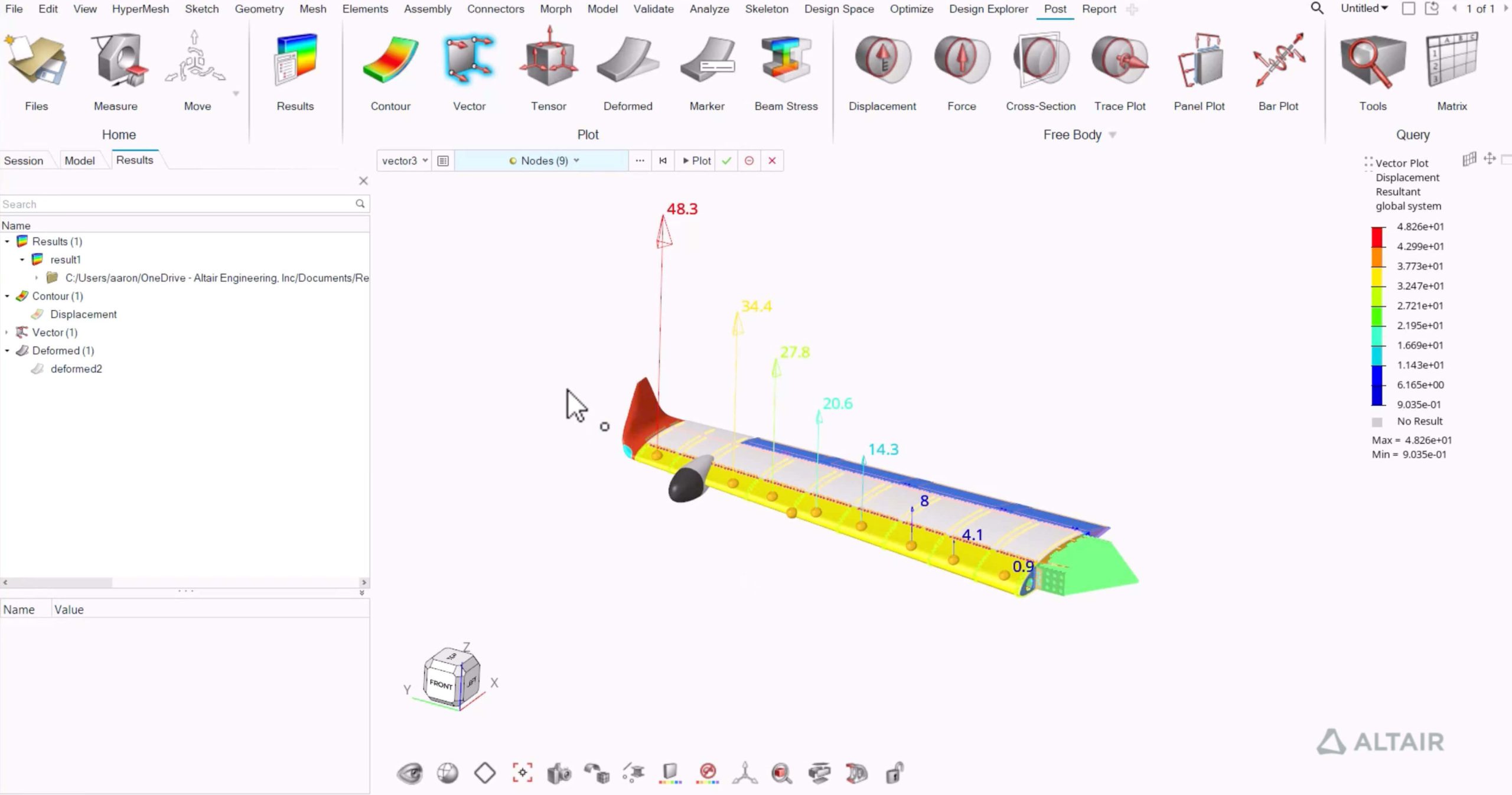

Results analysis and advanced visualization

HyperMesh post-processing enables detailed FEM results analysis through interactive visualizations, customizable graphs, and powerful data filtering tools. Engineers can quickly extract actionable insights to support data-driven, traceable design decisions.

Request the Hypermesh trial now

Try Hypermesh and explore advanced FEM modeling directly with your design.